| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | KXD |

| Model Number : | KXD-CAGE |

| Certification : | ISO9001,OHSAS18001,Product Patents |

| Price : | 10-50 USD per set |

| Payment Terms : | ,L/C,T/T,Western Union |

| Supply Ability : | 30000 sets Per Month |

| Delivery Time : | 15-35 days |

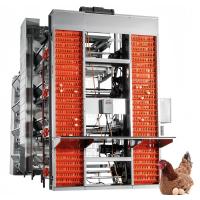

Chicken Raising Equipment Galvanized Steel H Type Poultry Cage Equipment For Layers

Introduction of KXD Layer cages

With factory production concept,we can built an environmentally farming enterprise ,includes layout of farm,feed factory,poultry breeding ,egg packing,organic fertilizer processing.

In addition to our comprehensive approach to layer farming, we also prioritize the well-being of our chickens through innovative design and technology. Our modern chicken coops are engineered to provide optimal living conditions, ensuring that each bird has ample space, proper ventilation, and access to natural light. This not only enhances the health and productivity of the layer chickens but also improves the quality of the eggs produced. We utilize high-quality, sustainable materials in the construction of our poultry cages, which are designed for easy maintenance and cleaning.

Layer Cage Feeding Details

| Battery Cage | Includes Support Legs, Cage, Trough, Feeding Trails |

Advantages: 1.The distance between adjacent leg is 1250mm.Width is 1300mm, add 5cm with top net of each tier . Formed by 2mm Zam (Zinc Aluminized Magnesium plate).C-shape,that ensure very strong. 2.Material strength reach more than 450MPa, and galvanized coat content must reach 275g/㎡. 3.All cage wire mesh adopt Belgium Bekaert galvanized aluminum wire(zinc-aluminum wire) . It is not only enhance greatly the anti rust. effect,but also improve the cage net surface smooth,to avoid hurting chicken scratch. 4.Feeding trough is made by 1mm ZAM. | |

| Feeding System | Includes Silo, Weight Sensor and Display, Main Feeding Line, Main Feeding Motor, Feed Sensor, Drop Pipe of Feed, Trolley , Driving System |

Feature: 1.Feeding trolley rail use 2mm hot-dip galvanized square tube . 2.The galvanized coat content of silo reach 275g/㎡ 3.Feeding trolley is adopted,one trolley one row | |

| Drinking System | Includes Silo, Weight Sensor and Display, Main Feeding Line, Main Feeding Motor, Feed Sensor, Drop Pipe of Feed, Trolley , Driving System |

Feature: 1.Medicator is adopted French DOSANTRON product 2.Digital water meter to display the consumption of water | |

| Egg-Collecting System | Includes Egg Elevator, Egg Belt, Driven System of Egg Belt, Tensioned Unit of Egg Belt |

Feature : Egg elevator adopt belt elevator which is reliable ,easy to operate and maintain. | |

| Manure-removing System | Includes PP Manure Belt, Driving Gear Motor of PP Belt, Scraper of Belt, Crosswise Manure Conveyor Indoors, Sloping Manure-conveyor |

Feature 1.Driving motor is adopted Aluminum alloy reducer. 2.Driving rollers are coated with whole rubber. 3.Scrapers are installed at the end of manure belt, and two secondary scrapers are installed below returning of the manure belt, so that manure can be cleared thoroughly. 4.cross manure conveyor and sloping conveyor ,the frame use galvanized sheet ,and belt use robber 6mm belt,it has a resistance of high temperature and low temperature. Also It has anti aging. | |

| Cooling and Ventilation | Includes Cooling Pad, Aluminum Frame of Cooling Pad, Cooling Water Circling System, 52’ High-negative Cone Fan |

Advantage: 1. Thickness of cooling pad 150mmm, Aluminum alloy frame with PVC bottom water tank. 2. 52' high-negative cone Fan, -25pa, the wind volume is . | |

| Lighting System | Led,T Type Wire, Wire Box, Dimmer |

| Power Controlling system | Includes Feeding Controlling System, Manure-removing System, Egg Collection System, Environment Controller, General Controlling, Alarm |

Feature: 1. Environment controller is from Munters Trio ,include 6 temperature sensors,1 humidity sensor,1 negative pressure sensor . 2. All the electrical component adopt Chinese CHNIT . 3. Two electricity box is placed ,one is in the front room which controls feeding system and egg-collecting system,the other box is placed in the back of house which controls fans. 4. All the cables in the house are protected by cable bridge. | |

| Checking Carts | Includes Removable Checking Cart, Electric cart |

| Note:All the products can be customized due to customers’ needs. | |

Silo Attributes

Core Components | Cone Plate | Galvanized coating | 275g/㎡ |

Warranty | 1 Year | Design | Accept |

Weight | 628 KG | Application | Poultry Farm Used Feed Storage |

Place of Origin | Shandong, China | Single package size | 260X110X150 cm |

Brand Name | KXD | Life | 25-40 Years |

Material | Galvanized Corrugated Sheets | Function | Grain Wheat Corn Storage Silos |

Machinery Test Report | Provided | Video Outgoing-inspection | Provided |

Drinker Nipple Details

Condition | New | Feature | 360 degree outer, Long Service Time Easy cleaning High performance |

Warranty | 1 Year | Application | Poultry Drinking |

| Color | Custom | Package | 14*13*4.5cm/one pack 28 nipples |

Place of Origin | Shandong, China | Farm Animals Type | Chicken Birds Ducks Geese Turkeys |

Brand Name | KXD | Operation | Full-automatic |

Size | 3.4cm*1.0cm | Installation | Support Online Installing& on-site installation |

Weight | 0.3 KG | Material | 304 Stainless Steel+PP |

Conveyor Manure Belt

PP conveyor belt with unique properties: high tensile strength, impact resistance, corrosion resistant, low-temperature resistant (can work in -50 degree centigrade), good toughness , low friction, which can adapt to various working environment abroad.

The PP conveyor belt Many poultry farms have this conveyor manure belt at home and can bear more than 230 kilos poultry manure per square meter.

A good smooth treatment, low friction, complete washing clean and no waste which can control breeding environment. The frosted surface can increase the friction between drive stroll and the conveyor belt, lower the coeffcient of slip-resistance and control deviation

Cooling Pad

Cooling Pad is a special paper honeycomb structure material, its working principle is "water evaporation absorb heat" this natural physical phenomenon. That is water in the role of gravity, from the top downward -ow, in the cooling pad corrugated per surface to form a water lm, when the ow of air through the cooling pad, the water lm in the water will evaporate to absorb the heat of the air to take away a lot of latent heat, so that after the wet curtain the air temperature is reduced. This will lower the temperature of the air passing through the cooling pad, thus achieving the purpose of cooling.

Cooling pad filter uses with cooling pad, lter water impurities, to prevent water and pipe blockage. The lter has the characteristic of advanced structure, small resistance, convenient pollution discharge.

Supports and Services:

The Steel Structure Poultry House product comes with comprehensive technical support and services to ensure efficient and effective installation, maintenance, and operation. Our team of experts are available to provide guidance and assistance throughout the process, including:

Our commitment to customer satisfaction means that we are always available to answer any questions or concerns that may arise, and we work tirelessly to ensure that our customers are fully satisfied with their purchase. We are dedicated to providing top-notch technical support and services for the Steel Structure Poultry House product.

FAQ

Q1: You are manufacture factory or trading company?

A: Manufacture factory.

Q2:What the quality assurance you provided and how do you control quality?

A: Established a procedure to check products at all stages of the manufacturing process - raw materials, in process materials, validated or tested materials, finished goods, etc. SGS, BV and other testing are available for us.

Q3:Is your price competitive compared with other' companies?

A: Our business objectives are to give the best price with same quality and best quality with the same price. We will do everything we can to reduce your cost and guarantee you get the best product that you paid for.

Q4: Can you send engineers or whole team to install my project?

A: Yes, we will send you the detailed installation drawing and video for free, we can provide the service of installation.supervision, and training by extra. We can send our professional technical team to supervise installation on site overseas.

Q5: Do you accept container loading inspection?

A: You are welcomed to send an inspector, not only for the container loading, but any time during the production time.

Q6: Do you offer designing service for us?

A: Yes, we could design full solution drawings as your requirements. By using Auto CAD, PKPM, MTS, 3D3S, Tarch, Tekla Structures (X steel) etc, we can design complex industrial building like office mansion, super marker, auto dealer shop, shipping mall, 5 stars hotel.

Q7: What is the delivery time?

A: Delivery time depends on order quantities. In general, the delivery time is 30 working days after receiving the deposit.

Q8: How can you get a quotation for your projects?

A: You can contact us by email, phone, WhatsApp, Skype, Viber and so on 24*7 and you will get reply within 8 hours.

Q9: How to ensure the product you supply is what we want exactly?

A: Before placing order, our sales and engineers' team will provide you the suitable solution according to your requirements.Proposal drawing, 3D drawing, Materials' photos, finished projects photos are available, which will help you understand the solution we provided deeply.

|